Showing posts with label

Activities of industrial engineering.

Show all posts

Showing posts with label

Activities of industrial engineering.

Show all posts

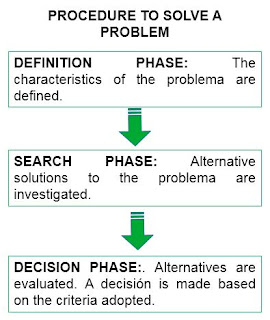

An introduction to the process of designing work methods – The

general procedure for solving problems

In

the general procedure for solving problems, three different phases

can be distinguished: i) a definition phase, ii) a search phase and

iii) a definition phase.

Definition

phase

It

consists of determining the characteristics of the problem, that is:

- The

specifications of the initial and final state.

- Existing

restrictions.

- The

criterion (preference).

- The

number of repetitions.

- The

time limit.

- This

includes a description of the data or constraints within which the

methods analyst must operate.

Search

phase

The

search process implies an inquiry regarding the alternative solutions

of the problem, that is, the different methods to achieve the

transformation of the initial state towards the end.

This

process is characterized by an investigation as exhaustive as

possible, to later carry out a synthesis. In this phase, the

ingenuity and inventiveness of the methods analyst plays an important

role.

Decision

phase

The

decision process consists of evaluating the alternatives obtained,

and then choosing based on the established criteria.

In

practice, the aforementioned phases of the problem-solving process

may have points in common, and it is often necessary to repeat the

cycle, with the corresponding feedback, before finding a satisfactory

solution.

An introduction to the process of designing work methods – The

characteristics of a problem

What

are the characteristics of a problem?

Being

familiar with the characteristics of a problem is one of the

foundations for its solution, since it facilitates the understanding

and scope of the design and the procedure that it implies, since the

design is, in essence, the solution to a problem that by tradition is

entrusted to the engineers.

Solving

an engineering problem, including of course related to methods

engineering, involves dealing with several different methods to

achieve the desired result. If there were no known or unknown

alternative solutions, there would be no problem.

If

all solutions were equally satisfactory, then there would not be a

problem either, however this is usually not the case, since a problem

involves finding a preferred method; for example, the least

expensive. Therefore, if the preferred method is obvious from the

beginning, there is also no problem.

In

any problem there is a set of initial circumstances (input, or

starting point) and a set of final circumstances (output, goal, or

result for which a method is sought). The characteristics of a

problem are listed below:

- The

number of possible solutions is, in general, large.

- Possible

solutions to a practical problem are seldom obvious at first. In

reality, it is not often that all possible solutions are known in

advance, even if prior analysis or research has been done.

- Alternative

solutions are not equally desirable, therefore the preferred solution

is sought, for which it is necessary to apply selection or decision

processes. In this way, the existence of methods with different

degrees of preference enables a fruitful search before making a

choice. The base of the preferences is usually called the criterion

and in various problems in the business world, this parameter is the

profit obtained; This allows choosing the best alternative among

various investment alternatives. Therefore, the method sought is the

one that maximizes the profit when time, money and other resources

are invested.

- The

relative advantage of alternative solutions to a problem is generally

not evident, and the search for data, measurements and calculations

must be carried out to determine it satisfactorily.

The

cost of time and other resources dedicated to solving a problem must

be considered in a reasonable way, since, as with many economic

concepts, a point is reached where it is more difficult to find

additional solutions and where productivity begins to decline.

descend. Thus, while the search for better methods continues, a point

in time is reached where better solutions are unlikely to be found

that justify a greater investment of time, money, and other

resources.

Can

a problem be solved perfectly?

There

are two reasons why a problem cannot be solved perfectly: i) the time

required for such a task would be greater than the life of the

problem, which is true for the vast majority of problems in the

industry and ii) it is not economically optimal to try to find a

perfect solution. It is more economical to direct efforts to other

problems that require solutions, before continuing to try to find a

perfect solution.

In

solving problems, it is not intended to find one that is completely

ideal, nor is it expected to find it, since there would be no

possibility of recognizing it as such if it were found. The idea that

is pursued is to progress towards the ideal solution, looking for

better solutions until it is determined that it is not productive to

continue with the search.

What is the importance of productivity and how to improve it

Creating goods and services in different areas requires that certain

resources be transformed into these (raw materials, supplies, labor,

etc.). The more efficiently the mentioned transformation happens, the

more productive it will be.

In its most basic form, productivity can be understood as the

proportion of outputs (goods and services) among the inputs

(resources such as raw materials, inputs, labor, capital, etc.).

Improving productivity it is of vital importance for any company.

Improving the ratio of outputs and inputs (productivity) will be one

of the most important tasks (if not the most important) that

industrial engineering and in general the directors of operations or

production face in their daily work.

How to improve productivity?

Productivity improvement can be achieved in the following ways:

either by reducing the inputs while the outputs are kept constant, by

increasing the outputs while the inputs are kept constant, or by

increasing the outputs and reducing the inputs at the same time. This

implies an increase in productivity.

From the economic perspective, the inputs can be identified as land,

labor, capital and management. These inputs are combined in a

production system. Through management, the conversion of inputs into

outputs can be achieved. The better the management the greater the

productivity that can be achieved in a given production system.

The outputs resulting from a production process can be goods or

services of various kinds (for example computers, calculators, cell

phones, soft drinks, education, hotels, etc.). Production then can be

viewed as all the goods and services produced. The fact of having a

high production may originate from an increasing number of people

working (which can lead to an increase in employment levels), however

this situation does not necessarily imply that there is a high

productivity.

Measuring productivity is a good way to assess a country's ability to

provide and improve the living standards of its inhabitants. The

increase in productivity is closely linked with the improvement in

productive capacity and therefore, in a macro context, it can lead to

an improvement in the standard of living.

Without an increase in productivity, the increase in the benefits

generated by the factors of production (labor, capital, land,

technology, management) implies an increase in prices. Conversely,

when productivity increases, prices tend to decrease since more is

produced with the same amount of resources.

About occupational health

and safety

Occupational health and safety is relevant in all branches of industry,

business and commerce including traditional industries, information technology

companies, care homes, schools, universities, leisure facilities and offices.

Occupational health and safety affects all aspects of work, that’s why high

hazard manufacturing plant requires many different specialists, such as

engineers (industrial, electrical, mechanical and civil), lawyers, medical

doctors and nurses, trainers, work planners and supervisors, may be required to

assist the professional health and safety practitioner in order to ensure that

there are satisfactory health and safety standards.

Generally, there are many obstacles in the process of achieve good

health and safety standards. The pressure of production or performance targets,

financial constraints and the complexity of the organization are typical

examples of such obstacles. However, there are powerful incentives for

organizations to strive for high health and safety standards. These incentives

are moral, legal and economic.

The corporate

responsibility and the relation with occupational health and safety

Corporate responsibility, a term used extensively in our days, covers a

wide range of issues. It includes the effects that an organization’s business

has on the environment, human rights and common welfare. Health and safety in

the workplace is an important corporate responsibility issue.

One

definition of corporate responsibility

Corporate responsibility has various definitions, however, broadly

speaking it covers the ways in which organizations manage their core business

to add social, environmental and economic value in order to produce a positive, sustainable impact on both society and the business

itself. Terms such as corporate social responsibility and socially responsible

business refer to this concept.

In terms of corporate responsibility, organizations must

work in order to:

- improve management systems to reduce

injuries and ill health

- demonstrate the importance of health and

safety issues at board level

- report publicly on health and safety

issues within their organization, including their performance against targets.

Effective management of health and safety:

- is vital to employee well-being

- has a role to play in enhancing the

reputation of businesses and helping them achieve high-performance teams

- is financially beneficial to business.

Definition of safety and industrial hygiene

Safety

at work

According to Bestratén (1999), safety at work is

"the set of techniques and procedures that are designed to

eliminate or reduce the risk of accidents."

Therefore, safety

at work is concerned with addressing a number of hazards that affect

industrial accidents, such as:

- Lack

of mechanisms of protection against moving parts of machinery,

equipment and tools;

- Poor

conditions of order and cleanliness in the workplace;

To achieve safety at work, we should develop preventive

actions that fall within both general and specific rules, such as:

- The mission and vision of the company;

- The safety policies;

- Procedures at work;

- Staff training;

- Incorporation of

safety devices on machines, equipment and facilities.

Industrial

hygiene

According to Hernandez and Marti (1989), industrial

hygiene is the discipline that aims the prevention of occupational

diseases by controlling chemical, physical or biological agents in

the working environment.

The (chemical, physical or biological) agents

mentioned have effect in the workplace; not only directly for workers

who perform a particular task, but also for people from other areas

that are part of that environment. Moreover, the presence of these

agents also affects the external environment of the company like

nearby businesses, nearby communities and in general the soil, air

and water.

In order to reduce occupational risks of emerging

pollutants, three objectives are established:

Controls on the origin and source of danger;

Controls on the path between the hazard and the

worker;

Controls on the subject exposed to danger.

Activities of industrial engineering

Most important activities of industrial engineering are:

- Development of time standards, costing and performance standards.

- Selection of processes and assembling methods.

- Selection and design of tools and equipment.

- Design of facilities including plant location, layout of building, machines and equipment, material handling system raw materials and finished goods storage facilities.

- Design and improvement of planning and control systems for production, inventory, quality and plant maintenance and distribution systems.

- Cost control systems.

- Development and installation of job evaluation systems.

- Installation of wage incentive schemes.

- Design and installation of value engineering and analysis system.

- Operation research.

- Mathematical and statistical analysis.

- Performance evaluation.

- Organization and methods.

- Supplier selection and evaluation.