An introduction to the process of designing work methods – The

general procedure for solving problems

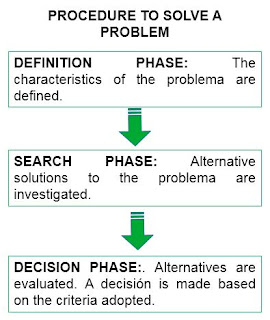

In

the general procedure for solving problems, three different phases

can be distinguished: i) a definition phase, ii) a search phase and

iii) a definition phase.

Definition

phase

It

consists of determining the characteristics of the problem, that is:

- The

specifications of the initial and final state.

- Existing

restrictions.

- The

criterion (preference).

- The

number of repetitions.

- The

time limit.

- This

includes a description of the data or constraints within which the

methods analyst must operate.

Search

phase

The

search process implies an inquiry regarding the alternative solutions

of the problem, that is, the different methods to achieve the

transformation of the initial state towards the end.

This

process is characterized by an investigation as exhaustive as

possible, to later carry out a synthesis. In this phase, the

ingenuity and inventiveness of the methods analyst plays an important

role.

Decision

phase

The

decision process consists of evaluating the alternatives obtained,

and then choosing based on the established criteria.

In

practice, the aforementioned phases of the problem-solving process

may have points in common, and it is often necessary to repeat the

cycle, with the corresponding feedback, before finding a satisfactory

solution.

An introduction to the process of designing work methods – The

characteristics of a problem

What

are the characteristics of a problem?

Being

familiar with the characteristics of a problem is one of the

foundations for its solution, since it facilitates the understanding

and scope of the design and the procedure that it implies, since the

design is, in essence, the solution to a problem that by tradition is

entrusted to the engineers.

Solving

an engineering problem, including of course related to methods

engineering, involves dealing with several different methods to

achieve the desired result. If there were no known or unknown

alternative solutions, there would be no problem.

If

all solutions were equally satisfactory, then there would not be a

problem either, however this is usually not the case, since a problem

involves finding a preferred method; for example, the least

expensive. Therefore, if the preferred method is obvious from the

beginning, there is also no problem.

In

any problem there is a set of initial circumstances (input, or

starting point) and a set of final circumstances (output, goal, or

result for which a method is sought). The characteristics of a

problem are listed below:

- The

number of possible solutions is, in general, large.

- Possible

solutions to a practical problem are seldom obvious at first. In

reality, it is not often that all possible solutions are known in

advance, even if prior analysis or research has been done.

- Alternative

solutions are not equally desirable, therefore the preferred solution

is sought, for which it is necessary to apply selection or decision

processes. In this way, the existence of methods with different

degrees of preference enables a fruitful search before making a

choice. The base of the preferences is usually called the criterion

and in various problems in the business world, this parameter is the

profit obtained; This allows choosing the best alternative among

various investment alternatives. Therefore, the method sought is the

one that maximizes the profit when time, money and other resources

are invested.

- The

relative advantage of alternative solutions to a problem is generally

not evident, and the search for data, measurements and calculations

must be carried out to determine it satisfactorily.

The

cost of time and other resources dedicated to solving a problem must

be considered in a reasonable way, since, as with many economic

concepts, a point is reached where it is more difficult to find

additional solutions and where productivity begins to decline.

descend. Thus, while the search for better methods continues, a point

in time is reached where better solutions are unlikely to be found

that justify a greater investment of time, money, and other

resources.

Can

a problem be solved perfectly?

There

are two reasons why a problem cannot be solved perfectly: i) the time

required for such a task would be greater than the life of the

problem, which is true for the vast majority of problems in the

industry and ii) it is not economically optimal to try to find a

perfect solution. It is more economical to direct efforts to other

problems that require solutions, before continuing to try to find a

perfect solution.

In

solving problems, it is not intended to find one that is completely

ideal, nor is it expected to find it, since there would be no

possibility of recognizing it as such if it were found. The idea that

is pursued is to progress towards the ideal solution, looking for

better solutions until it is determined that it is not productive to

continue with the search.

Basic

definitions related to occupational

health and safety

Some

basic and powerful definitions related to occupational health and

safety are the following:

Health

Related

to the protection of the bodies and minds of people from illness

resulting from the materials, processes or procedures used in the

workplace.

Safety

Related to the

protection of people from physical injury. The borderline between

health and safety is ill-defined and the two words are normally used

together to indicate concern for the physical and mental well-being

of the individual at the place of work.

Welfare

Related

to the provision of facilities to maintain the health and well-being

of individuals at the workplace. Welfare facilities include washing

and sanitation arrangements, the provision of drinking water,

heating, lighting, eating and rest rooms. First aid arrangements are

also considered as welfare facilities.

Occupational or

work-related ill-health

Is concerned with those

illnesses or physical and mental disorders that are either caused or

triggered by workplace activities. Such conditions may be induced by

the particular work activity of the individual or by activities of

others in the workplace. The time interval between exposure and the

onset of the illness may be short or long.

Environmental

protection

Related

to the arrangements to cover those activities in the workplace which

affect the environment and, possibly, the health and safety of

employees and others.

Accident

Defined

as any unplanned event that results in injury or ill health of

people, or damage or loss to property, plant, materials or the

environment or a loss of a business opportunity.

Near miss

Is any incident that

could have resulted in an accident.

Dangerous occurrence

It’s

a near miss which could have led to serious injury or loss of life.

Hazard and risk

A hazard is the

potential of a substance, activity or process to cause harm. Hazards

take many forms including, for example, chemicals, electricity and

working from a ladder.

A

risk is the likelihood of a substance, activity or process to cause

harm. A risk can be reduced and the hazard controlled by good

management.

The difference

between hazard and risk

It

is very important to distinguish between a hazard and a risk – the

two terms are often confused and activities such as construction work

are called high risk when they are high hazard. Although the hazard

will continue to be high, the risks will be reduced when controls are

implemented.

The residual risk

The level of risk

remaining when controls have been adopted is known as the residual

risk. There should only be high residual risk where there is poor

health and safety management and inadequate control measures.

Productivity and industrial engineering

What

is productivity?

Applied

in an enterprise, a sector of economic activity or the economy as a

whole, productivity may be defined as an output and input relation.

The

term productivity can be used to asses or measure the extent to which

a certain output can be extracted from a given input. This may

appears simple enough in cases where both the output and the input

are tangible and can be easily measured; however, in cases where

intangibles are introduced measure of productivity can be more

difficult.

Calculation

of productivity

Productivity

can be calculated as follows:

Productivity

and industrial engineering in goods production

In

the case of goods production, the objective is the manufacturing to a

better cost, through the raw material, with productivity of the

primary resources of production: Materials, human resources and

machines. It's on these, where the action of industrial engineers

should address their efforts. Increasing productivity indexes and

reducing production costs, are fundamental tasks of an industrial

engineer.

Productivity, types of productivity, productivity index, total productivity

Whats is productivity?

Productivity is the ratio of output to some or all of the resources used to produce the output.

Types of productivity

We can mention the following types of partial productivities:

- Labor productivity: units produced / hours worked

- Capital productivity: output / capital input

- Material productivity: output /material input

What is the productivity index?

We can calculate a type of partial productivity as labor productivity as output per man hours for a complete year. These figures obtained from year to year can be indexed and can be related to a base year so that output per man our comparisons can be made.

Definition of total productivity

It is the ratio of tangible output and tangible input.

Differences among partial productivity, total factor productivity and total productivity

Men, materials, machines, methods, money, energy, etc. are inputs.

- Partial productivity: output / one class of input

- Total factor productivity: net output / (labor + capital)

- Total productivity : sum of all tangible outputs / sum of all tangible inputs

Methods design, motion and time study

What’s methods design

Methods design is the analysis of the various ways a task can be done so as to establish the one best way. It includes motion analysis (the study of the actions the operator can use and the advantages and/or disadvantages of each variation) and standardization of procedure (the selection and recording of the selected and authorized work methods).

While ‘‘time and motion study’’ is the more commonly used term, it is more correct to use ‘‘motion and time study,’’ as the motion study to establish the standard procedure must be done prior to the establishment of a standard time to perform that work.

Motion study definition

Motion study can be defined as “the analysis of the manual and the eye movements occurring in an operation or work cycle for the purpose of eliminating wasted movements and establishing a better sequence and coordination of movements.”

Time study definition

Time study can be defined as “the procedure by which the actual elapsed time for performing an operation or subdivisions or elements thereof is determined by the use of a suitable timing device and recorded. The procedure usually but not always includes the adjustment of the actual time as the result of performance rating to derive the time which should be required to perform the task by a workman working at a standard pace and following a standard method under standard conditions.”

Attempts have been made to separate the two functions and to assign each to a specialist. Although motion study deals with method and time study deals with time, the two are nearly inseparable in practical application work. The method determines the time required, and the time determines which of two or more methods is the best. It has, therefore, been found best to have both functions handled by the same individual.

Methods engineering and workplace design

Workplace design

Material usually flows through a facility, stopping briefly at stations where additional work is done on it to bring it closer to a finished product. These workstations, or workplaces, must be designed to permit performance of the required operations, to contain all the tooling and equipment needed to fit the capabilities and limitations of the people working at them, to be safe and to interface smoothly with neighboring workplaces.

Human engineering and ergonomic factors must be considered so that all work, tools, and machine activation devices are not only within the comfortable reach of the operator but are designed for safe and efficient operation. A workplace chart which analyzes the required actions of both hands is an aid in workplace design.

Methods engineering and Process analysis

Methods engineering definition

Methods engineering is concerned with the selection, development, and documentation of the methods by which work is to be done. It includes the analysis of input and output conditions, assisting in the choice of the processes to be used, operations and work flow analyses, workplace design, assisting in tool and equipment selection and specifications, ergonomic and human factors considerations, workplace layout, motion analysis and standardization, and the establishment of work time standards.

A primary concern of methods engineering is the integration of humans and equipment in the work processes and facilities.

What’s Process analysis?

Process analysis is that step in the conversion of raw materials to a finished product at which decisions are made regarding what methods, machines, tools, inspections and routings are best. In many cases, the product’s specifications can be altered slightly, without diminishing its function or quality level, so as to allow processing by a preferred method. For this reason, it is desirable to have the product’s designer and the process engineer work together before specifications are finalized.

Methods Engineering and Work Simplification in Industrial Engineering

These reactions led to an increased interest in the work of the Gilbreths. Their efforts in methods analysis, which had previously been considered rather theoretical and impractical, became the foundation for the resurgence of industrial engineering in the 1920s and 1930s. In 1927, H. B. Maynard, G. J. Stegmerten, and S. M. Lowry wrote Time and Motion Study, emphasizing the importance of motion study and good methods. This eventually led to the term methods engineering as the descriptor of a technique emphasizing the “elimination of every unnecessary operation” prior to the determination of a time standard. In 1932, A. H. Mogenson published Common Sense Applied to Time and Motion Study, in which he stressed the concepts of motion study through an approach he chose to call work simplification. His thesis was simply that the people who know any job best are the workers doing that job. Therefore, if the workers are trained in the steps necessary to analyze and challenge the work they are doing, then they are also the ones most likely to implement improvements. His approach was to train key people in manufacturing plants at his Lake Placid Work Simplification Conferences so that they could in turn conduct similar training in their own plants for managers and workers. This concept of taking motion study training directly to the workers through the work simplification programs was a tremendous boon to the war production effort during World War II.

The first Ph.D. granted in the United States in the field of industrial engineering was also the result of research done in the area of motion study. It was awarded to Ralph M. Barnes by Cornell University in 1933 and was supervised by Dexter Kimball. Barnes’s thesis was rewritten and published as Motion and Time Study: the first full-length book devoted to this subject. The book also attempted to bridge the growing chasm between advocates of time study versus motion study by emphasizing the inseparability of these concepts as a basic principle of industrial engineering.

Another result of the reaction was a closer look at the behavioral aspects associated with the workplace and the human element. Even though the approach taken by Taylor and his followers failed to appreciate the psychological issues associated with worker motivation, their work served to catalyze the behavioral approach to management by systematically raising questions on authority, motivation, and training. The earliest writers in the field of industrial psychology acknowledged their debt to scientific management and framed their discussions in terms consistent with this system.