An introduction to the process of designing work methods – The

general procedure for solving problems

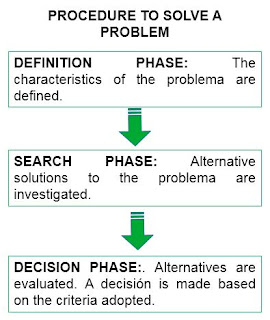

In

the general procedure for solving problems, three different phases

can be distinguished: i) a definition phase, ii) a search phase and

iii) a definition phase.

Definition

phase

It

consists of determining the characteristics of the problem, that is:

- The

specifications of the initial and final state.

- Existing

restrictions.

- The

criterion (preference).

- The

number of repetitions.

- The

time limit.

- This

includes a description of the data or constraints within which the

methods analyst must operate.

Search

phase

The

search process implies an inquiry regarding the alternative solutions

of the problem, that is, the different methods to achieve the

transformation of the initial state towards the end.

This

process is characterized by an investigation as exhaustive as

possible, to later carry out a synthesis. In this phase, the

ingenuity and inventiveness of the methods analyst plays an important

role.

Decision

phase

The

decision process consists of evaluating the alternatives obtained,

and then choosing based on the established criteria.

In

practice, the aforementioned phases of the problem-solving process

may have points in common, and it is often necessary to repeat the

cycle, with the corresponding feedback, before finding a satisfactory

solution.

An introduction to the process of designing work methods – The

characteristics of a problem

What

are the characteristics of a problem?

Being

familiar with the characteristics of a problem is one of the

foundations for its solution, since it facilitates the understanding

and scope of the design and the procedure that it implies, since the

design is, in essence, the solution to a problem that by tradition is

entrusted to the engineers.

Solving

an engineering problem, including of course related to methods

engineering, involves dealing with several different methods to

achieve the desired result. If there were no known or unknown

alternative solutions, there would be no problem.

If

all solutions were equally satisfactory, then there would not be a

problem either, however this is usually not the case, since a problem

involves finding a preferred method; for example, the least

expensive. Therefore, if the preferred method is obvious from the

beginning, there is also no problem.

In

any problem there is a set of initial circumstances (input, or

starting point) and a set of final circumstances (output, goal, or

result for which a method is sought). The characteristics of a

problem are listed below:

- The

number of possible solutions is, in general, large.

- Possible

solutions to a practical problem are seldom obvious at first. In

reality, it is not often that all possible solutions are known in

advance, even if prior analysis or research has been done.

- Alternative

solutions are not equally desirable, therefore the preferred solution

is sought, for which it is necessary to apply selection or decision

processes. In this way, the existence of methods with different

degrees of preference enables a fruitful search before making a

choice. The base of the preferences is usually called the criterion

and in various problems in the business world, this parameter is the

profit obtained; This allows choosing the best alternative among

various investment alternatives. Therefore, the method sought is the

one that maximizes the profit when time, money and other resources

are invested.

- The

relative advantage of alternative solutions to a problem is generally

not evident, and the search for data, measurements and calculations

must be carried out to determine it satisfactorily.

The

cost of time and other resources dedicated to solving a problem must

be considered in a reasonable way, since, as with many economic

concepts, a point is reached where it is more difficult to find

additional solutions and where productivity begins to decline.

descend. Thus, while the search for better methods continues, a point

in time is reached where better solutions are unlikely to be found

that justify a greater investment of time, money, and other

resources.

Can

a problem be solved perfectly?

There

are two reasons why a problem cannot be solved perfectly: i) the time

required for such a task would be greater than the life of the

problem, which is true for the vast majority of problems in the

industry and ii) it is not economically optimal to try to find a

perfect solution. It is more economical to direct efforts to other

problems that require solutions, before continuing to try to find a

perfect solution.

In

solving problems, it is not intended to find one that is completely

ideal, nor is it expected to find it, since there would be no

possibility of recognizing it as such if it were found. The idea that

is pursued is to progress towards the ideal solution, looking for

better solutions until it is determined that it is not productive to

continue with the search.

Investigation of accidents at work - What incidents should be

investigated?

In

general, everything related to incidents at work must be monitored by

the administration of a company. However, there are several events of

a different nature that, due to their possible impact on the normal

development of the organization's activities, should be the subject

of an investigation. Within this framework, a large part of the

country's legislation provides for the investigation of at least

those events whose impact or severity is relevant.

For

example, when a death occurs in the workplace or accidents that cause

severe damage to the health of workers occur, especially if they are

recurring, investigation processes are surely required, which is

required by the competent authorities in matters of occupational

health and safety.

Generally,

the competent authorities require a formal investigation and reports

in this regard, in the following cases:

- Any

accident with severe damage to the health of workers or death,

incidents involving the collapse of structures and situations

involving the use of hazardous substances.

- Incidents

that result in workers requiring medical treatment.

Incidents

that could have generated catastrophic damage, but did not. In this

context, companies can establish standards that help determine the

cases in which an incident should be the subject of a formal

investigation (these standards must minimally comply with the

requirements of the labor authorities). In this way, the occupational

health and program of a company could establish, for example, the

following criteria to activate an investigation and the corresponding

report to the authorities:

- Any

event that causes physical harm to workers, including those that

require medical help, or causes prolonged interruptions of normal

activities;

- Any

event that requires recurring medical treatment;

- Any

incident that goes against the company's accident prevention policy;

- Any

event that has had the potential to cause physical damage to workers;

- Any

event of serious damage to company property;

- Any

event of poisoning by chemical substances;

- Any

event that has generated a flood in the work environments;

- Any

event that has generated a fire or explosion.

Critical factors in the incident and accident investigation

process

Incidents

that materialize in accidents are generally the result of several

interacting factors, which is why area supervisors must undertake

accident investigation in coordination with personnel specialized in

occupational health and safety. In this way, they must focus on three

essential factors: the human, the situational and the environmental

or environment.

Human

factors

Beyond

the training they may have, due to their human nature, the attitudes

and way of acting of the workers can become a source for the

occurrence of incidents. Thus, the following questions should be

asked when investigating the human factors related to an accident:

- What

was the worker doing at the time of the incident?

- Was

he doing a regular or special task?

- Was

he doing maintenance work?

- Was

he helping a partner?

- Was

the worker performing his or her work in accordance with established

procedures?

- Are

the tasks or work procedures new?

- Was

the area supervisor present?

- What

was the employment status of the worker? Are you a seasonal,

part-time, or full-time worker?

- How

much experience did the worker have to perform the task he was

developing?

- What

was the worker's posture and location?

- Did

any unsafe act contribute to the occurrence of the event?

Situational

factors (unsafe conditions)

The

analysis of possible unsafe conditions is a central element in the

investigation of accidents, so the equipment and tools must be

carefully examined. In this sense, the following questions should be

asked when carrying out the analysis of situational factors:

- Was

he being the machine properly?

- Were

the controls working properly?

- Were

the security measures working satisfactorily?

- Did

the analysis of materials or equipment indicate how the accident

occurred?

- What

was the place or location of the incident?

- What

tools, equipment or objects were involved in the incident?

- Was

the right equipment available to do the job?

- Was

personal protective equipment being used?

- Were

the machinery guards in place?

- What

time did the accident occur?

- What

work shift were you operating at the time of the incident?

Environmental

or surrounding factors

Environmental

factors such as light or noise can increase the likelihood of an

incident occurring. For example, if the reflection of light prevents

a machine operator from seeing clearly, this could lead to an

accident. Likewise, the noise generated by some machine could prevent

hearing the movement of vehicles or people in the work area.

Critical factors in the incident and accident investigation

process

The

investigation of incidents and accidents is closely linked to the

opportunity, severity (ie impact) and legal requirements.

The

opportunity in the investigation of incidents and accidents

Opportunity

is a critical factor in the investigation of incidents and accidents,

since time has a crucial impact on the generation of any type of

information. Delays in an investigation could cause the parties

involved to partially or completely forget the circumstances of the

occurrence of an accident, in addition to changes in the place of the

event or the loss of valuable evidence.

In

the case of people, if the investigation is not started in a short

period of time, it is highly possible that the details of the

circumstances of the accidents present distortions and the witnesses

do not provide reliable and accurate information.

The

investigation process should start immediately after people who may

have been affected by an incident are cared for and the scene of the

incident is secured to prevent further harm.

The

severity or impact

Since

any investigation requires time, companies must prioritize the

allocation of more resources to those incidents with the most

relevant consequences. This applies even to accidents that have not

generated significant damage, but due to their characteristics could

have a significant impact at some point.

Thus,

it is recommended that the following types of incidents be

investigated with greater emphasis:

- Those

that result in damage that generates a loss of time beyond the day of

the incident;

- Those

in which the personal damages have been minor, but the potential

damage has been high.

- Incidents

with property damage greater than USD1,000;

- Incidents

with loss of time resulting from the aggravation of previous damage.

In

general, beyond the system used by a company to determine the

severity of an incident, there is a legal obligation to report all

incidents that result in personal injury to employees.

Legal

requirements

Depending

on the severity of an incident, the presence of physical damage and

the jurisdiction where it occurred, certain reporting requirements to

the competent authorities must be met. Certain types of events, such

as those in which medical help is required or result in significant

loss of time, must be reported to special instances related to

workers' compensation mechanisms.

Investigation of incidents

and accidents in occupational health and safety

Incident

investigation is a fundamental component of any organization's

occupational health and safety program. Different studies identify

the benefits of incident investigation as follows:

Direct

determination of the causes: An investigation reveals the direct

causes of an incident, allowing corrective measures to be

established.

Identification

of associated factors: Incidents can be the result of many

factors, for example, the direct cause of an incident can be the

inadequate use of protective equipment on the machines, however,

there can also be associated factors, such as the lack of training in

handling equipment.

Prevention

of similar incidents: Once the direct causes and associated

factors are identified, corrective measures such as training programs

or improvements in the design of equipment or workplaces are

implemented to prevent similar incidents in the future.

Creation

of permanent reports: The reports generated in an investigation

can be used by the human resources area and occupational health and

safety specialists to identify trends related to the frequency of

incidents, inadequate plant design and layout, inadequate operating

procedures, etc. Reports are also important in situations where

compensation disputes or claims arise. The actions taken to improve

occupational health and safety records contribute decisively to

adequately allocate monetary, human and equipment resources to the

areas with the highest frequency of accidents or to those where the

effects are most harmful.

Determination

of associated costs: The reports help to understand a certain

situation more precisely and therefore to quantify and determine the

costs associated with the occurrence of an incident. All factors,

including lost time by workers, damage to equipment and machinery,

loss of supplies and materials, etc. they are likely to be

quantified, a task that can be better accomplished from the reports

that are part of the incident investigation.

Promotes

a culture of employee safety: When an incident investigation is

conducted appropriately, it signals to workers that top management

takes occupational health and safety seriously, seeking to maintain

the well-being of employees. The foregoing motivates the company's

workers, regardless of the area where they work or their rank, to

have a greater commitment to good safety and health practices in the

workplace.

Etiquetas:

Batch of one,

Continuos improvement,

Just in time,

Kan-ban,

Manufacturing methodologies,

Process analysis,

Production engineering,

Production systems,

Pull system,

Push system,

Statistical process control

The techniques used in the “pull” production system

The "pull" manufacturing system is characterized by producing only what is required, minimizing inventory in process. To achieve this end, several particular approaches have been created, such as those described below:

Just-in Time: In which only the appropriate components, at the precise moment they are required, are manufactured.

Kan-Ban: It is a paper record that enforces just-in-time, moving with each batch of components. This can be automated using barcodes, QR codes, etc.

Manufacturing cells: Combine the requirements of a variety of products so that a set of equipment can produce each of them, as needed. This mainly applies to manufacturing and sometimes to assembly.

Batch-of-One: Refers to the ability to make any combination of items with a batch size as small as one.

Continuous improvement: Refers to the ability to find ways to improve current processes, often by combining and/or eliminating manufacturing activities.

Statistical process control: Referred to monitoring how well the process is working.

The manufacturing process had played a secondary role in product design for most of the 20th century, resulting in many problems when it came to manufacturing the products. While major aspects of manufacturing processes have been researched and implemented in physical devices for many years, the assembly process had very little beyond the rules of thumb to guide it.

Ideas for improving assembly capability and for designing cost-effective manufacturing systems only began to flourish in the late 1970s. During this period, many individuals and companies began to realize that the most rational course of action involved design. of products and the design of manufacturing systems together, which is called concurrent engineering or simultaneous engineering. A more recent term, which involves the entire company as well as suppliers and customers, is known as collaborative engineering.

Manufacturing methodologies – the pull and push systems

Traditionally, there has been a clear separation between the creation of a product and the means through which it is produced. In much of the 20th century, manual production methods were used in different processes, especially those in which assembly was present. However, many important design decisions were worked on behind a desk.

Between the late 1970s and throughout the 1980s, manufacturing industries of all types and sizes wanted to know how they could replace their manual production methods with better processes. In this way, large companies that produced larger volumes of a product determined that automation was the best solution. In this way robots and other programmable machines were developed. Manufacturing plants of this era were characterized by having work-in-process inventory that took up large amounts of space, creating significant costs that did not generate revenue.

In the 1990s, up to the present day, industries of all sizes need to be agile and flexible, so a new paradigm in the field of production was introduced. This approach means that companies are looking to have the ability to respond to any customer very quickly, while minimizing their costs. Thus, the production philosophy changed from making a stock of some product to manufacturing on demand, which required rethinking the way in which production processes should be carried out.

In this framework, Toyota introduced the approach of producing only what is required, with which the "pull" method replaced the "push" method.

In the “push” production method, each stage of the manufacturing process ran at the highest possible speed, regardless of what happened in subsequent stages, which meant having significant batches of inventory in process. To optimize these processes, elaborate simulation methods were created.

In the "pull" method of production, each stage of the manufacturing process works only when the next stage provides notice that it requires inputs. Viewed another way, each step in the process has a customer, either internal or external, to which it responds. Using this system, inventories in process are minimized, being completely eliminated in many cases. The analysis of such a manufacturing system is much less complex than traditional simulation methods.

Producing only what is required is a fundamental concept of "pull" manufacturing systems, which minimizes in-process inventory. Work is not done in any area until the next level says it is ready for input.